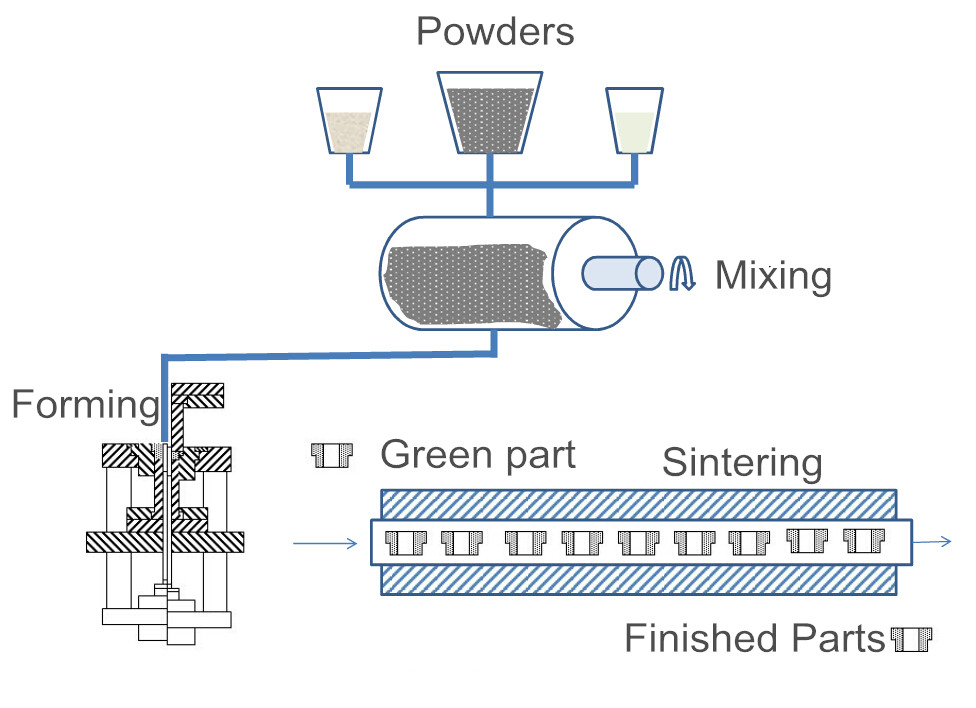

Basically, powder metallurgy consists of 4 steps, feedstock, molding, sintering, follow-up treatments.

Feedstock

Generally, there are two ways to produce metal powders: mechanical process, physical-chemical process. And mechanical process consists of mechanical pulverization and atomization method. Physical-chemical process consists of Electrochemical corrosion method, reduction method, chemical combination, Reduction–combined method, vapour deposition method, Liquid Phase Deposition and electrolytic process.

Molding

After molding, the feedstock become a designed shape, with certain density and strength. There are two methods of molding: pressure molding and no-pressure molding.

Sintering

Sintering is the key process. The formed parts obtain the designed mechanical properties after sintering.

Follow-up Treatments

Follow-up treatment selection depends on the requirements of customers. Such as machining, oil impregnation, heating, electronic plating, blackening, passivation, etc. Almost all of treatments could be done on PM parts as done on the parts made by conventional manufacturing processing.

English

English German

German Spanish

Spanish French

French Italian

Italian Portuguese

Portuguese Japanese

Japanese Korean

Korean Arabic

Arabic Russian

Russian Chinese

Chinese NO.2 Machinery

NO.2 Machinery NO.2 Machinery

NO.2 Machinery SINTS

SINTS